The Rise of China CNC Turning Parts: Transforming the Metal Fabrication Industry

In recent years, the manufacturing landscape has undergone a profound transformation, largely driven by advancements in technology and the increasing demand for precision engineering. Among these advancements, China CNC turning parts have emerged as a pivotal factor, reshaping the metal fabrication industry not only in China but across the globe. This article seeks to delve into the intricacies of CNC turning, its advantages, applications, and the overarching influence it has on the future of manufacturing.

Understanding CNC Turning: A Brief Overview

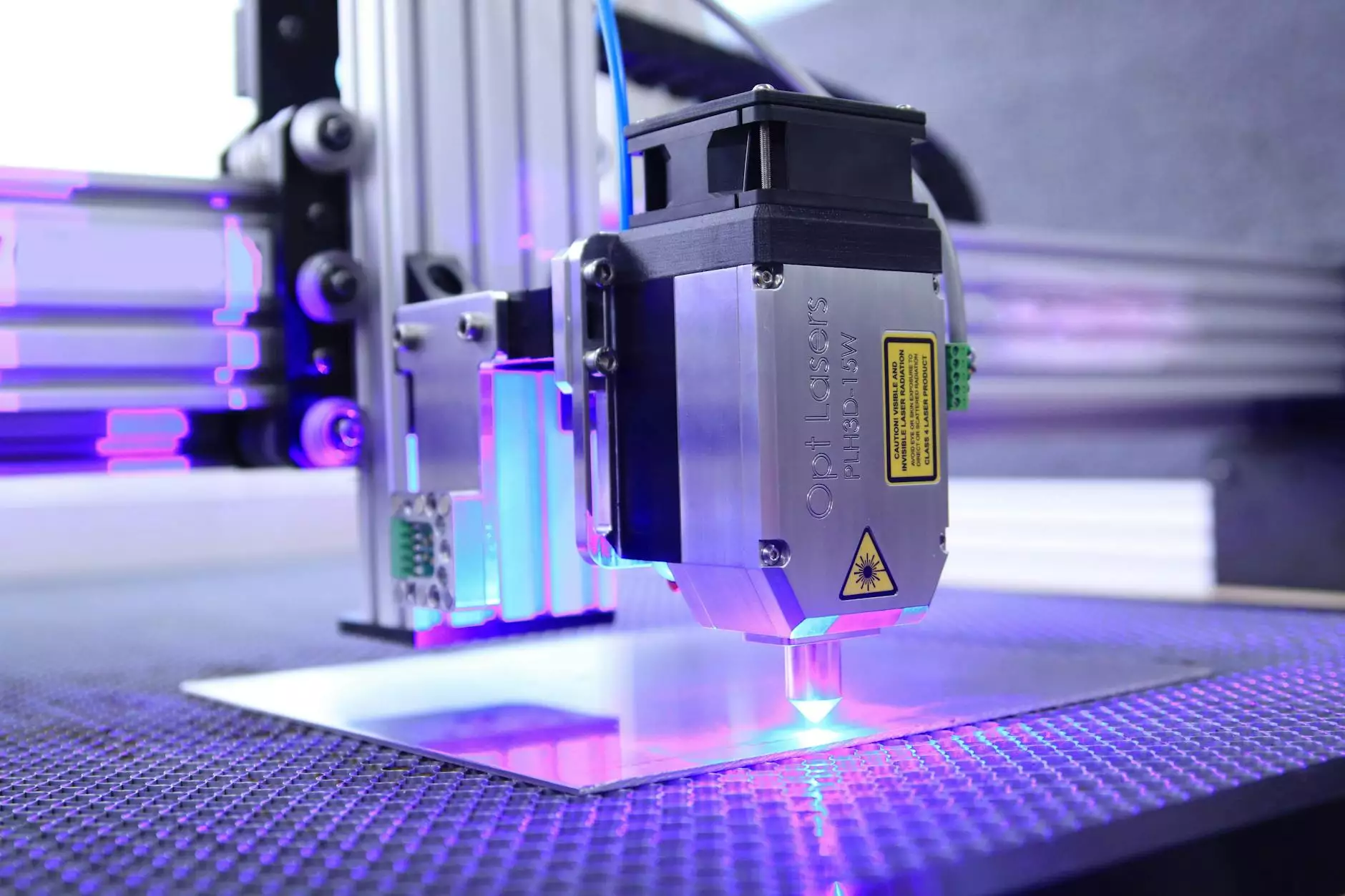

Computer Numerical Control (CNC) turning is a manufacturing process used to create cylindrical parts from raw material stock. Utilizing a computer program to control the machinery, CNC lathes remove material from a workpiece, which can be rotated at high speeds, ensuring high precision and repeatability. The integration of highly sophisticated software and machinery results in products that meet rigorous specifications and quality standards.

The Process of CNC Turning

The CNC turning process involves the following steps:

- Design: Engineers create a detailed design using Computer-Aided Design (CAD) software.

- Programming: The design is translated into a CNC program using Computer-Aided Manufacturing (CAM) software.

- Setup: Raw materials are securely fixed on the CNC lathe.

- Machining: The machine begins to remove material to achieve the desired dimensions and finish.

- Quality Control: Finished parts undergo inspection to ensure they meet specifications.

Advantages of China CNC Turning Parts

The demand for China CNC turning parts is bolstered by several advantages that set them apart from traditional manufacturing methods:

1. High Precision and Consistency

CNC turning machinery is capable of producing parts with unmatched accuracy. The predictable nature of computer control allows for minimal human error, ensuring that each part is manufactured consistently to exact specifications. This is crucial in industries such as aerospace, automotive, and medical, where precision is paramount.

2. Increased Efficiency

The automation provided by CNC turning dramatically enhances production speed. Parts can be produced much faster than with manual machining methods, enabling manufacturers to meet increasing levels of demand without compromising on quality. Furthermore, CNC machinery can operate continuously, leading to higher output rates and reduced lead times.

3. Versatility in Material Usage

CNC turning can be applied to a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers in China to accommodate varying customer requirements and product specifications, making China CNC turning parts a sought-after solution in diverse industries.

4. Cost-Effectiveness

Although the initial investment in CNC machinery can be significant, the long-term savings achieved through increased productivity, reduced waste, and lower labor costs make it an economically viable option. Companies are discovering that the ability to produce parts at a lower cost while maintaining quality is a substantial competitive advantage.

Applications of China CNC Turning Parts

The applications of CNC turning parts are broad and varied, reflecting their importance across multiple sectors:

Aerospace Industry

In the aerospace sector, precision-engineered components are critical. CNC turning enables manufacturers to produce complex designs for engine components, landing gear, and structural elements, all of which must adhere to stringent safety and performance standards.

Automotive Industry

The automotive industry relies heavily on CNC turning for the production of components such as gear shafts, bearings, and hydraulic valves. The demand for lightweight and high-strength materials in vehicle manufacturing further accentuates the need for precise CNC turning solutions.

Medical Field

In the medical field, CNC turning is utilized to create surgical instruments, implants, and prosthetics. The necessity for sterile, precise, and functional components drives the demand for high-quality CNC turning services.

Electronics and Telecommunications

The electronics sector leverages CNC turning for casings, connectors, and heat sinks. The precision required for modern electronic devices necessitates reliable manufacturing processes, which CNC turning effectively provides.

Future Trends in CNC Turning and Manufacturing

As technology continues to advance, the landscape of CNC turning and the manufacturing industry is poised for further evolution:

1. Incorporation of Advanced Materials

Future CNC turning will likely see the integration of advanced materials such as carbon fiber and titanium alloys, which offer strength and lightness while also being challenging to machine. This necessitates the development of new tools and techniques to accommodate these materials.

2. Automation and Smart Manufacturing

With the rise of the Industrial Internet of Things (IIoT), CNC machines are becoming increasingly connected. This smart manufacturing trend will allow for real-time monitoring and adjustments, predictive maintenance, and significant improvements in efficiency and productivity.

3. Sustainability Practices

As global awareness of environmental issues rises, there is a concerted push towards sustainability in manufacturing. Efficient resource management, waste reduction, and energy-efficient practices are becoming paramount in the CNC turning landscape.

Why Choose DeepMould for China CNC Turning Parts?

For companies looking to leverage the benefits of China CNC turning parts, choosing the right partner is critical. At DeepMould, we embrace the latest technologies to produce high-quality CNC turning parts that meet the stringent demands of various industries.

Our Commitment to Quality

Quality is not just a priority; it is our promise. With robust quality control systems in place, we ensure that all our products undergo rigorous testing and inspection before they reach our clients. Our state-of-the-art machinery and skilled workforce contribute to our reputation for excellence.

Competitive Pricing

We understand the importance of cost-effectiveness in manufacturing. Therefore, our CNC turning services are designed to provide high quality at competitive prices, ensuring that your business remains profitable while receiving the parts you need.

Customized Solutions

At DeepMould, we believe in bespoke solutions. We work closely with our clients to understand their specific needs and provide tailored services that conform to their manufacturing requirements, whether they need high volumes or specialized components.

Conclusion: Embracing the Future of CNC Turning

As we look to the future, China CNC turning parts are set to play a pivotal role in the evolution of the global manufacturing industry. The benefits of precision, efficiency, and versatility underscore the need for businesses to adapt and integrate CNC turning technologies into their operations. With companies like DeepMould leading the charge, the possibilities for innovation and advancement in metal fabrication are limitless.

Embrace the future of manufacturing with China CNC turning parts—where technology meets precision and quality.